Pharmacy Albarello

During the event called "Conversations about restoration"

During the event called "Conversations about restoration"

held in Genoa in April 2011 at the Lomellino Palace in Via Garibaldi, the restorers Elisabetta Solari and Elena Panarello gave a talk on:

"How to recognise the cause of deterioration in a ceramic artefact: a comparison of skills"

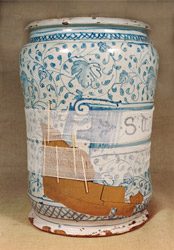

The piece we are going to present is an Italian maiolica pharmacy vase, decorated in monochrome cobalt blue, 30cm high with a diameter at its widest of 20cm. Presumably Ligurian, it can be placed between the 16th and 17th centuries.

The piece we are going to present is an Italian maiolica pharmacy vase, decorated in monochrome cobalt blue, 30cm high with a diameter at its widest of 20cm. Presumably Ligurian, it can be placed between the 16th and 17th centuries.

Characterized by a cylindrical body, slightly tapered at the centre and curved at the ends, it rests on a large round base with quite a pronounced out-splayed rim. The container surface is completely glazed except for its base.

Italian maiolica is a type of porous fine-mix ware and in this case it is an ochre colour, obtained by carbonate-rich clay whose glassy coating, opacified by the presence of tin oxide is called "tin glaze", usually white, in this case it is slightly blue in tint due to a small percentage of cobalt oxide. The use of tin glaze is a technique of Arabian origin and probably occurred whilst trying to imitate Chinese porcelain, with the first examples dating from the 9th and 10th centuries AD found in Mesopotamia. In Europe they appear mainly in the Islamised regions such as the Iberian peninsula or Sicily, and then spread through the rest of Europe from the 1400s onwards.

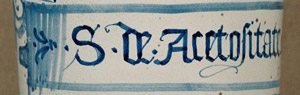

T he term maiolica comes from the island of Majorca, a busy Mediterranean port, numerous ceramic products were distributed from there. The most accredited etymological origin of albarello today leads us back to the Arabic word al barain, to describe a spool shape, one of the most common of those intended for pharmaceutical use. Used as a container for ointments and syrups, it was usually covered by parchment secured by twine around the rim. Eastern influences are also discernible in the decoration in cobalt blue of leafy volutes evolved from the decorative calligraphic motif that is the background to the scroll bearing the Latin inscription S.D. Acetositate (Syrupus De Acetositate) in Gothic script, referring to the substance in the container. Both its shape and decoration correspond to a type of Ligurian production that was heavily influenced by the nearby East, even if no direct evidence has been found. When the vase arrived in our studio a large part of its facing was detached and extremely fragmented. Using a grazing light to examine the external surface of the artefact it was seen how almost all of the glassy coating risked coming away due to a series of more or less evident cracks that crossed it both lengthwise and crosswise. In the area of the enamel detachment, moreover, it was clear that the uncovered central crack principally involved the biscuit, and only continued partially on the enamel. The detachment of an are

he term maiolica comes from the island of Majorca, a busy Mediterranean port, numerous ceramic products were distributed from there. The most accredited etymological origin of albarello today leads us back to the Arabic word al barain, to describe a spool shape, one of the most common of those intended for pharmaceutical use. Used as a container for ointments and syrups, it was usually covered by parchment secured by twine around the rim. Eastern influences are also discernible in the decoration in cobalt blue of leafy volutes evolved from the decorative calligraphic motif that is the background to the scroll bearing the Latin inscription S.D. Acetositate (Syrupus De Acetositate) in Gothic script, referring to the substance in the container. Both its shape and decoration correspond to a type of Ligurian production that was heavily influenced by the nearby East, even if no direct evidence has been found. When the vase arrived in our studio a large part of its facing was detached and extremely fragmented. Using a grazing light to examine the external surface of the artefact it was seen how almost all of the glassy coating risked coming away due to a series of more or less evident cracks that crossed it both lengthwise and crosswise. In the area of the enamel detachment, moreover, it was clear that the uncovered central crack principally involved the biscuit, and only continued partially on the enamel. The detachment of an are a of coating in antique Italian maiolica is not unusual given that body and glaze have different expansion coefficients. However, it is unusual for this to happen suddenly, from one day to the next, without apparently plausible reasons, as described by the owner, and moreover to affect such an extensive part of the vase. After consulting staff at the Faenza Institute of Science and Technology of Ceramic Materials, it was concluded that not having formations of saline bloom between the enamel and the biscuit as a reason for the defect, the only answer was that there had been insufficient adhesion between the two materials at the production stage. Of all the hypotheses the only one that can explain not only the glaze detachment but also the body fractures is that during the drying or firing phase, or even both, latent tensions and cracks were formed in the earthenware. Another plausible explanation that concurs with the first one, is that excessive firing of the biscuit resulted in a decrease in porosity - particularly in the surface - thus limiting the ability of the glaze to adhere.

a of coating in antique Italian maiolica is not unusual given that body and glaze have different expansion coefficients. However, it is unusual for this to happen suddenly, from one day to the next, without apparently plausible reasons, as described by the owner, and moreover to affect such an extensive part of the vase. After consulting staff at the Faenza Institute of Science and Technology of Ceramic Materials, it was concluded that not having formations of saline bloom between the enamel and the biscuit as a reason for the defect, the only answer was that there had been insufficient adhesion between the two materials at the production stage. Of all the hypotheses the only one that can explain not only the glaze detachment but also the body fractures is that during the drying or firing phase, or even both, latent tensions and cracks were formed in the earthenware. Another plausible explanation that concurs with the first one, is that excessive firing of the biscuit resulted in a decrease in porosity - particularly in the surface - thus limiting the ability of the glaze to adhere.

Basically, it was considered that the origin of the problem was inherent in the initial condition of the object, in the chemical-physical-structural c haracteristics of its constituent materials, in the presence of defects caused by the production technique used as well as interaction with the environment in which it was placed. A particular situation, a thermal shock (it had been a particularly hot summer) saw the problem degenerate. Urgent intervention was necessary to halt such rapid and progressive deterioration so, in agreement with Faenza CNR, it was decided to consolidate in a 5% solution of Paraloid B72 acrylic resin in nitro. Then in some of the most insecure points parts were fixed with a few drops of cyanoacrylate adhesive. The vase was then wrapped in a light gauze to guarantee the sealing of the glaze during immersion in the consolidating solution. To ensure the removal of the gauze afterwards did not endanger the seal coating, small wooden rods were inserted between the two to prevent a total adherence. Once drying had finished - a phase that required quite a long time - any excess adhesive and consolidator was cleaned off the surface, the macro-cracks were filled with epoxy resins and the fragments were fixed using a 60% solution of Paraloid B72 diluted in acetone. The missing parts were reintegrated using cellulosic plaster coloured with pigments, choosing a slightly subdued colour shade that echoes the underlying colour of the maiolica.

haracteristics of its constituent materials, in the presence of defects caused by the production technique used as well as interaction with the environment in which it was placed. A particular situation, a thermal shock (it had been a particularly hot summer) saw the problem degenerate. Urgent intervention was necessary to halt such rapid and progressive deterioration so, in agreement with Faenza CNR, it was decided to consolidate in a 5% solution of Paraloid B72 acrylic resin in nitro. Then in some of the most insecure points parts were fixed with a few drops of cyanoacrylate adhesive. The vase was then wrapped in a light gauze to guarantee the sealing of the glaze during immersion in the consolidating solution. To ensure the removal of the gauze afterwards did not endanger the seal coating, small wooden rods were inserted between the two to prevent a total adherence. Once drying had finished - a phase that required quite a long time - any excess adhesive and consolidator was cleaned off the surface, the macro-cracks were filled with epoxy resins and the fragments were fixed using a 60% solution of Paraloid B72 diluted in acetone. The missing parts were reintegrated using cellulosic plaster coloured with pigments, choosing a slightly subdued colour shade that echoes the underlying colour of the maiolica.